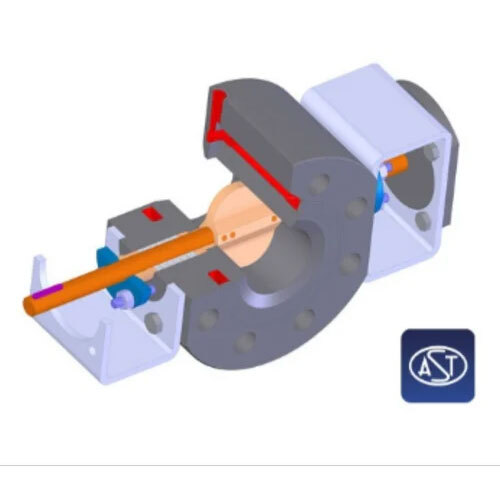

Crane Butterfly Valve

500.00 INR/Number

Product Details:

- Connection Other

- Usage Different Lining and Metallurgy to suit a wide variety of applications including sea water & water desalination plants

- Valve Type Wafer Type Butterfly Valve

- Material Other

- Size 80 mm to 3000 mm

- Power Source Hydraulic

- Product Type Wafer Type Butterfly Valve

- Click to View more

X

Crane Butterfly Valve Price And Quantity

- 500.00 INR/Number

- 1 Number

Crane Butterfly Valve Product Specifications

- Wafer Type Butterfly Valve

- Round

- Blue

- Medium

- Other

- Different Lining and Metallurgy to suit a wide variety of applications including sea water & water desalination plants

- Hydraulic

- High Pressure

- Wafer Type Butterfly Valve

- Water

- 1 Year

- 80 mm to 3000 mm

- Other

Crane Butterfly Valve Trade Information

- Vadodara, Gujarat

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 100 Number Per Week

- 6 Days

- Standard

- All India, Bihar, Kerala, North India, Karnataka, Maharashtra, Mizoram, Dadra and Nagar Haveli, Delhi, Jharkhand, Pondicherry, Telangana, Sikkim, Gujarat, Nagaland, Arunachal Pradesh, Chhattisgarh, Punjab, Uttar Pradesh, Meghalaya, Madhya Pradesh, Tripura, West India, East India, Tamil Nadu, Himachal Pradesh, Uttarakhand, Lakshadweep, Goa, Jammu and Kashmir, Andaman and Nicobar Islands, Haryana, Daman and Diu, West Bengal, Central India, Odisha, Rajasthan, Manipur, Chandigarh, South India, Andhra Pradesh, Assam

Product Description

With huge understanding, we are engaged in trading and supplying a wide gamut of Industrial Butterfly Valves. The offered valves are sourced from our trusted vendors in accordance with current market standards. These valves are widely used in gas, chemicals, oil and automobile industries for concatenating several pipe lines in transmitting water or other fluid materials. The provided valves are acknowledged all across the country for its durability. Furthermore, clients can avail these Industrial Butterfly Valves at industry leading prices.

Features:

-

Accurate dimensions

-

Corrosion proof

-

Simple to fit

Specifications:

Benefits at a glance:

- Actuator flange accommodates all types of actuators

- Positive shutoff bi-directionally

- Ease of maintenance

- Short face-to-face dimension

- Stem bushing reduces torque and isolates the stem from the valve body, preventing seizure

- Smooth finished disc flats to give a highly efficient seal

- Precision profile disc provides bubble-tight shut-off and ensures minimum torque and longer seat life

- Qualified for both gaseous and liquid service

- Crane Butterfly Valve Supplier In India

- Crane Butterfly Valve Supplier in Gujarat

- Crane Butterfly Valve Supplier in Vadodara

Versatile High-Pressure Valve Solution

Designed to endure high-pressure environments, the Crane Wafer Type Butterfly Valve is perfect for applications such as seawater, desalination plants, and other water-based processes. With a hydraulic power source and a robust construction, it ensures dependable sealing and flow control in a range of industrial settings.

Flexible Customization and Sizing

Offering a comprehensive size range from 80 mm to 3000 mm, and a selection of custom colors, this valve can be tailored to specific project requirements. Different lining and metallurgical options further enhance its compatibility with various media and guarantee long-lasting service life.

Reliable Indian Manufacturing and Distribution

As a leading distributor, manufacturer, and supplier in India, we prioritize stringent quality control and support. Our expertise ensures timely product delivery and technical assistance throughout your project's lifespan.

FAQ's of Crane Butterfly Valve:

Q: How does the Crane Wafer Type Butterfly Valve operate in high-pressure water applications?

A: This valve is designed with robust materials and a tight-sealing mechanism to handle high-pressure water and seawater scenarios. Its hydraulic actuation allows precise control even at large diameters, making it ideal for demanding environments such as desalination plants.Q: What sizes and custom options are available for this butterfly valve?

A: The Crane Wafer Type Butterfly Valve is available in sizes ranging from 80 mm to 3000 mm. Additionally, customers can choose custom colors and specify different linings and metallurgies to ensure compatibility with various water treatment applications.Q: When should different lining or metallurgy options be selected for this valve?

A: The selection depends on the media and environmental conditions. For example, specific linings and metallurgy should be chosen to resist corrosion in seawater handling or to meet application demands in water desalination processes, ensuring optimal valve longevity and performance.Q: Where can this valve be installed effectively?

A: These valves are commonly used in water treatment plants, desalination facilities, and other industries dealing with water and seawater processes. Their versatile design supports a wide range of installation environments where reliable flow isolation is needed.Q: What is the benefit of choosing a hydraulic power source for this Wafer Type Butterfly Valve?

A: A hydraulic power source provides strong, consistent actuation, particularly useful for larger valves and high-pressure systems. This ensures smooth and reliable operation, even under challenging conditions.Q: How are you supported when sourcing this valve in India?

A: As an established Indian distributor, manufacturer, and supplier, we offer comprehensive technical support, product customization, and timely delivery, ensuring the right solution reaches you as per your project specifications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free