Sanitary Centrifugal Pump Supplier in India

Product Details:

- Noise Level Low db

- Features Strong build, Low maintenance cost, Highly efficient and effective.

- Theory Centrifugal Pump

- Usage Industrial

- Material Metal

- Structure Single Stage Pump

- Product Type Centrifugal Pump

- Click to View more

Sanitary Centrifugal Pump Supplier in India Price And Quantity

- 1 Unit

Sanitary Centrifugal Pump Supplier in India Product Specifications

- Medium Pressure

- As per model Millimeter (mm)

- Industrial

- Centrifugal Pump

- Metal

- Strong build, Low maintenance cost, Highly efficient and effective.

- As per model Millimeter (mm)

- Centrifugal Pump

- Single Stage Pump

- Low db

Sanitary Centrifugal Pump Supplier in India Trade Information

- Cash Advance (CA)

- 100 Unit Per Week

- 7 Days

- All India

Product Description

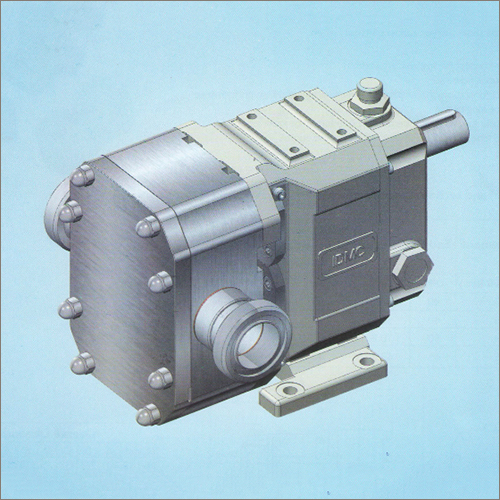

Our organization is enormously recommended as the top manufacturer and supplier of the Sanitary Centrifugal Pump Supplier in India. It is commonly used in agricultural, domestic and industrial applications for solvents, acids, oils, bases, pumping water and any kind of thin liquids. The offered pumps are made by using the top grade quality raw materials and modern techniques, under the directions of our team of expert professionals. We ensure our products are highly suitable for involving low viscosity fluids and admired for its flawless functioning and high efficiency. Apart from this, we customise the range of the Sanitary Centrifugal Pump Supplier in India in various sizes and dimensions at pocket-friendly prices.

Premium Quality Sanitary Centrifugal Pumps

Our sanitary centrifugal pumps are crafted from high-grade metal to maintain superior hygiene and performance. Designed for single-stage operation and medium-pressure requirements, these pumps ensure reliable fluid transfer for a wide spectrum of industrial uses. Experience long-term dependability with equipment built to rigorous quality standards.

Complete Solutions from Indias Trusted Supplier

We serve as a comprehensive source for sanitary centrifugal pumps, acting as a distributor, exporter, manufacturer, and supplier across India. Our broad network enables us to meet bulk and customized demands, catering to the needs of industries focused on hygienic fluid handling.

FAQs of Sanitary Centrifugal Pump Supplier in India:

Q: How does a sanitary centrifugal pump function in industrial environments?

A: A sanitary centrifugal pump works by converting rotational energy from the motor into kinetic energy, propelling fluids outward via the pumps impeller. This mechanism ensures hygienic and efficient fluid transfer, ideal for environments where cleanliness and process control are prioritized.Q: What materials are used in your centrifugal pumps, and why is metal preferred?

A: Our centrifugal pumps are constructed from high-quality metal, which provides structural integrity, resistance to corrosion, and compliance with sanitary standards. Metal is favored for its durability and ability to withstand rigorous industrial cleaning and usage.Q: When should a single-stage centrifugal pump be selected for industrial use?

A: Single-stage centrifugal pumps are recommended when the application demands moderate pressure and efficient fluid movement. They are preferred in industries where hygienic transfer and straightforward operation are essential, such as food processing and pharmaceuticals.Q: Where are your sanitary centrifugal pumps commonly utilized within industries?

A: These pumps are commonly found in food processing plants, pharmaceutical manufacturing units, chemical industries, and other facilities requiring sanitary handling of fluids. Their design supports low-maintenance and reliable operation in these settings.Q: What is the typical process for ordering or customizing pumps from your company?

A: Clients can initiate their order by contacting our sales team with their specific requirements. We offer customization options in terms of capacity, connection type, and finish. After design approval, production is carried out, followed by thorough quality checks prior to shipment.Q: How can these pumps benefit industrial operations?

A: Our sanitary centrifugal pumps enhance process efficiency by enabling quick and hygienic fluid transfers, lowering maintenance needs, and reducing operational downtime. Their metal construction assures long service life and compliance with hygiene protocols.Q: What usage maintenance is recommended for optimal pump performance?

A: To sustain optimal performance, regular inspection, cleaning, and lubrication of moving parts are advisable. It is also important to replace worn seals and check alignment periodically, thereby ensuring longevity and preventing contamination.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free